Multi-Sensor Data Fusion for Target Tracking

The Easy Guide to Integrating Multiple Sensors in Systems that Detect and Track Targets

Multi-sensor systems are frequently used in defence, security and maritime environments to provide effective target detection and tracking capabilities.

The combined data from multiple sensors can provide a clear and comprehensive view of the operational situation, supporting fast and effective decision-making.

The difficulty in building such a system lies in transforming raw and often conflicting sensor data into a single useful display.

The Challenge

Modern systems that identify and track targets often rely on a diverse range of sensors, including primary and secondary radars, AIS, ADS-B, RF, acoustic, and even EO/IR devices and cameras. Each sensor may have its own data format, update rate and level of credibility.

Without effective integration, operators can easily be overwhelmed by redundant or inconsistent information. This may lead to confusion, delayed decision-making, and potential operational risks.

One such example is seen when a single moving target is detected simultaneously by two different sensors, each with differing levels of accuracy. Poor integration may result in two targets being displayed, or it may treat both sensors with equal credibility, providing an inaccurate target location.

Cambridge Pixel's Solutions

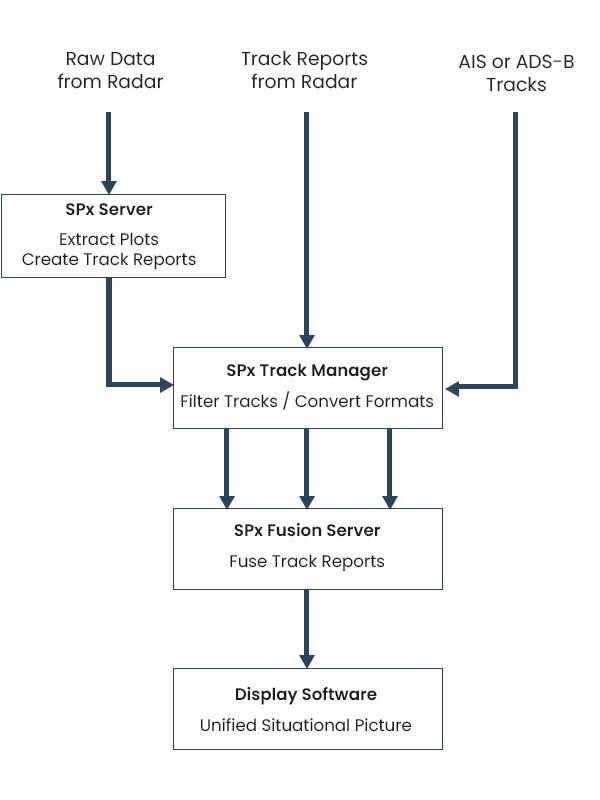

For radars and sensors without built-in tracking, the SPx Server software solution reliably extracts plots (targets) from raw data and outputs the data as track reports/messages in a chosen format.

Track reports from other sources may be provided in the sensor manufacturer's proprietary data format or an open standard such as ASTERIX.

These can be converted into a single chosen format using SPx Track Manager, which can also filter out irrelevant targets, include adjustments, or create additional data streams for dual redundancy.

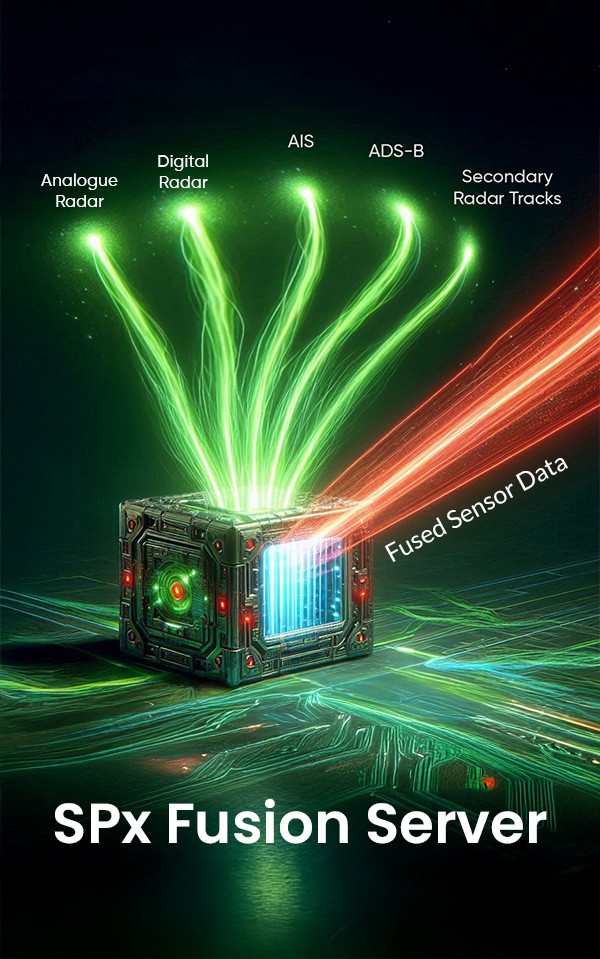

Where sensor coverage overlaps, multiple track reports may be received for the same target. SPx Fusion Server can receive track reports from up to 32 inputs, either directly from sensors or via SPx Server or SPx Track Manager, and intelligently fuse the best data into a single stream for output to displays and other systems.

Sensors with a limited range or field of view, such as EO/IR devices and cameras, can be steered towards tracks generated from other sensors, such as radars. Known as slew-to-cue, this capability features in some operator software, including VSD and RadarWatch, and can be added to other systems using SPx Camera Manager.

Intelligent Track Fusion for Accuracy

When combining track reports, advanced processing is needed to deliver the most accurate and reliable operational picture. SPx Fusion Server has many additional processing features, including:

-

Prioritisation and Scoring: Assign different levels of priority and credibility to individual sensors. When multiple sensors detect the same target, the system uses configurable rules to select the most reliable observation, eliminating erroneous or less accurate data.

-

Consistent Track IDs: Ensure that a single target is represented by a unique and consistent track ID across all fused data, even when detected by multiple overlapping sensors. This prevents duplication and provides a clear, unified view.

-

Comprehensive Data Enrichment: Where different sensors provide unique attributes (e.g., radar provides reliable position, AIS provides vessel identity), SPx Fusion Server combines this information into a single, enriched track report, providing operators with a complete understanding of each target.

-

Scalability and Flexibility: SPx Fusion Server can be scaled to handle complex multi-sensor environments and integrates seamlessly with Cambridge Pixel’s other radar processing and display products, allowing for highly customised solutions.

The Benefits of Unified Situational Awareness

By transforming raw data from multiple sensors into a single, cohesive operational picture, Cambridge Pixel's solutions deliver tangible advantages:

-

Enhanced Decision-Making: Operators gain a clear, uncluttered, and highly reliable view, enabling faster, more confident, and more accurate responses to threats or evolving scenarios.

-

Reduced Operator Workload: Automated data fusion minimises the need for manual correlation and analysis, freeing operators to focus on critical tasks and strategic decisions.

-

Improved Operational Efficiency: A unified and accurate situational display streamlines operations across all domains, from maritime surveillance and port security to military command and control, enabling more effective resource deployment and improving mission success.

-

Increased Reliability and Resilience: By cross-referencing data from multiple sources, the system enhances the robustness of target detection and tracking, even in challenging environments or if a single sensor fails.

-

Cost-Effective Flexibility: By providing individual, interoperable software modules, customers benefit from a more flexible and affordable solution, selecting only the capabilities required.

-

Ease of Integration: Cambridge Pixel is committed to supporting Open Standards, provides hardware-agnostic technology, and has a team of highly experienced engineers to provide expert customer support.

Find out more:

Visit the SPx Fusion Server product page to learn more about its capabilities for fusing sensor data.

For a more technical guide, read our Engineering Insights article: Fusing Video and Radar Tracks in Multi-sensor Military Security.

If you're interested in using our solutions to build or enhance your system, contact us to receive expert advice from our engineers.